One of the challenges in the design of hybrid diffractive/refractive optical systems is their effective simulation. The mixture of large area and micro- to nanoscaled structures makes modelling of diffractive structures difficult, especially when realistic diffracting structures need to be taken into account. Here, the distribution of unwanted stray light depends on fabrication effects and varies with the local periodicity of the diffractive optical element (DOE) and the illumination wavelength. We have realized an approach based on the local grating approximation that can be implemented into commercial ray tracing software[1].

The basic idea is to use the standard local grating approximation (LGA) approach with a diffraction efficiency database that takes into account local fabrication limitations and other above-mentioned dependencies. This can be an analytical model, a numerical model or even a model fed from experimental data. For each incoming ray one diffraction order is chosen upon the probability depending from the incoming ray data (angle, wavelength) and the local grating parameters (line density, orientation). If the system contains several diffractive elements, this allows an automatic and efficient further splitting of the power with emphasis on fast convergence of the most important orders with the ray number.

Our implementation in ZEMAX uses the built-in scatter functionality with a self-programmed dynamic link library (DLL) to integrate the more realistic diffractive simulation [1]. This implementation works in classical sequential mode, which allows us to use numerous analysis and even some available functions for optimization. The first model we used for the calculation of the diffraction effiencies was simple scalar diffraction on rotational symmetric diffraction gratings with continuously changing periods that were fabricated by gray scale laser writing. Here, the diffraction limited writing spot limits the quality of the obtained structures. Other models might take into account the effects of alignment errors in multi-step mask processes or even riorously computed diffraction efficiencies. For calculation efficiency purposes basic results are transfered to the RAM to create a look-up table that are then linearly interpolated on each single raytrace. This approach still permits quite efficient ray tracing with only about two times increased calculation time.

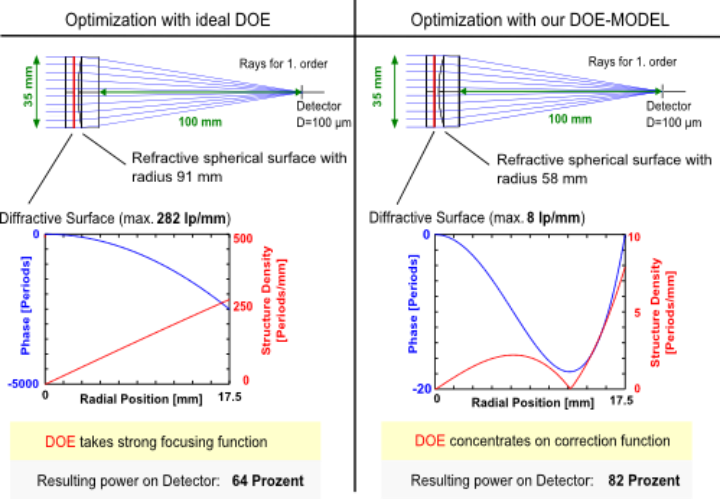

One of the most important benefits of the new simulation capability is that it can be used within an automated optimization process. This allows taking into account fabrication constraints quantitatively during the optimization. Fig. 1 shows optimization results for a simple system, that focusses light onto a detector with finite size. The system consists of a DOE and a plano-convex lens. Free parameters are the radius of the refractive lens and the aspheric phase function of the DOE, which is zero at the beginning of the optimization.

With the standard diffractive surface in ZEMAX, the optimizer puts a considerable amount of power into the DOE, reducing the formation of spherical aberration but leading to high line densities, since there is no penalty for the reduced diffraction efficiency because of difficulties in fabricating those structures

The more realistic DOE simulation leads to considerably reduced line densities. Here, the refractive lens is given more power (radius 58 mm instead of 91 mm) and the diffractive surface with lower power concentrates more on the correction. We simulated the fabrication for both designs and calculated the amount of light that would reach the detector. We obtained 82% for the optimization with the realistic model vs. only 64% for the design with conventional optimization.

Supported by: BMBF (FKZ 13N9456), Project: “MIMODIA”

Publications

- C. Pruss, R. Reichle, and W. Osten, "Realistic modeling of diffractive optical elements," EOS Topical Meeting on Diffractive Optics 2010, ISBN 978-3-00-024193-2, Koli, Finland: 2010, p. 2444