Diffractive optics and micro-optics offer options that are superior to conventional optics. Various manufacturing technologies, mostly on the basis of lithography techniques, are used for their fabrication. At our institute, the computer-controlled laser direct writing has been successfully used for years. Our writing systems work in polar coordinates, which has some significant advantages over conventional x/y-systems: The axes are completely independent and can therefore be very precisely controlled. The fabrication of rotationally symmetric optics simplifies dramatically. Very high scan rates can be achieved, which is particularly important for large, high-resolution computer-generated holograms (CGH).

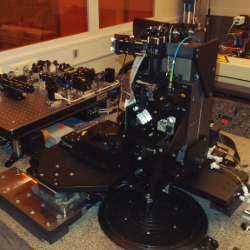

Direct laser Writing

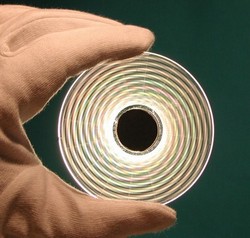

Direct laser writing is an established tool for the flexible, fast, and cost efficient fabrication of diffractive optical elements. In general, the system consists of a writing beam (405nm) that is focused onto a substrate which is coated with photoresist. The substrate is mounted on a rotating spindle and the writing beam can be moved in radial direction. For the fabrication of grayscale structures the writing beam intensity can be controlled (Fig. 1). The working principle is very similar to that of a Blu-ray burner: The substrate is on a turntable that rotates with a certain angular velocity. The writing head moves radially outward and is driven synchronously to the rotary movement.

Writing Systems

CLWS300M (Production System)

The working horse is used for our daily fabrication of DOEs for internal use aswell as contract work.

| Smallest feature sizes: | < 0.5µm (binary) |

| Max. substrate size: | Ø 300 mm |

| Max. substrate thickn.: | 25 mm |

| Write speed (typ.): | on-axis: 9 mm/h |

| off-axis: 4 mm/h | |

| Wavelength: | 405 nm |

| Positioning increment: | radial: 0.6 nm |

| azimuthal: 1'' @ 600 rpm |

CLWS300F (Research System)

| Smallest feature sizes: | < 0.5µm (binary) |

| Max. substrate size: | Ø 300 mm |

| Max. substrate thickn.: | > 25 mm |

| Wavelength: | 405 nm |

Processes

We are using processes for binary as well as multilevel structures:

Binary structuresThermochemically (chromium/chromoxid) or photochemical (photoresist) Applications:

|

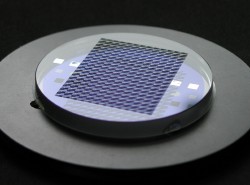

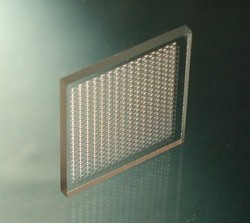

Multilevel structuresgraylevel direct laser writing in photoresist or grayscale masks Applications:

|

Application Examples

CGH for asphere testing High frequency axicon structure

Diffractive structure on a curved substrate

Micro optical components of a phase shifting point source array for interferometry with dynamic reference

Galvanically structured diffractive copper beam shaping optic for applications with high energy lasers in material processing

Two-sided beam shaping optic for solid state lasers

References

- A. G. Poleshchuk, E. G. Churin, V. P. Koronkevich, V. P. Korolkov, A. A. Kharissov, V. V. Cherkashin, V. P. Kiryanov, A. V. Kiryanov, S. A. Kokarev, and A. G. Verhoglyad. Polar coordinate laser pattern generator for fabrication of di.ractive optical elements with arbitrary structure. Applied Optics, 38(8):1295–1301, 1999.

- S. Reichelt, R. Freimann, and H. J. Tiziani. Absolute interferometric test of Fresnel zone plates. Optics Communications, 200:107–117, 2001.

- C. Pruss, S. Reichelt, V. P. Korolkov, W. Osten, and H. J. Tiziani. Performance improvement of CGHs for optical testing. In W. Osten, editor, Optical Measurement Systems for Industrial Inspection III, volume 5144 of Proceedings of SPIE, pages 460–471. SPIE–The International Society for Optical Engineering, 2003.

- M. Häfner, C. Pruss, W. Osten, Laser direct writing Recent developments for the making of diffractive optics, Opt. &Photonik. (2011) 40–43.

- M. Haefner, C. Pruss, W. Osten, Laser direct writing of rotationally symmetric high-resolution structures., Appl. Opt. 50 (2011) 5983–9.